?Three-dimensional mixer is a kind of mixer, widely used in pharmaceutical, chemical, food, light industry and other industries of the new material mixer. It can evenly mix the powder or granular materials with good fluidity, so that the mixture can achieve the best mixing effect. So where is the three-dimensional mixer applicable? What are the characteristics of three-dimensional motion mixer?

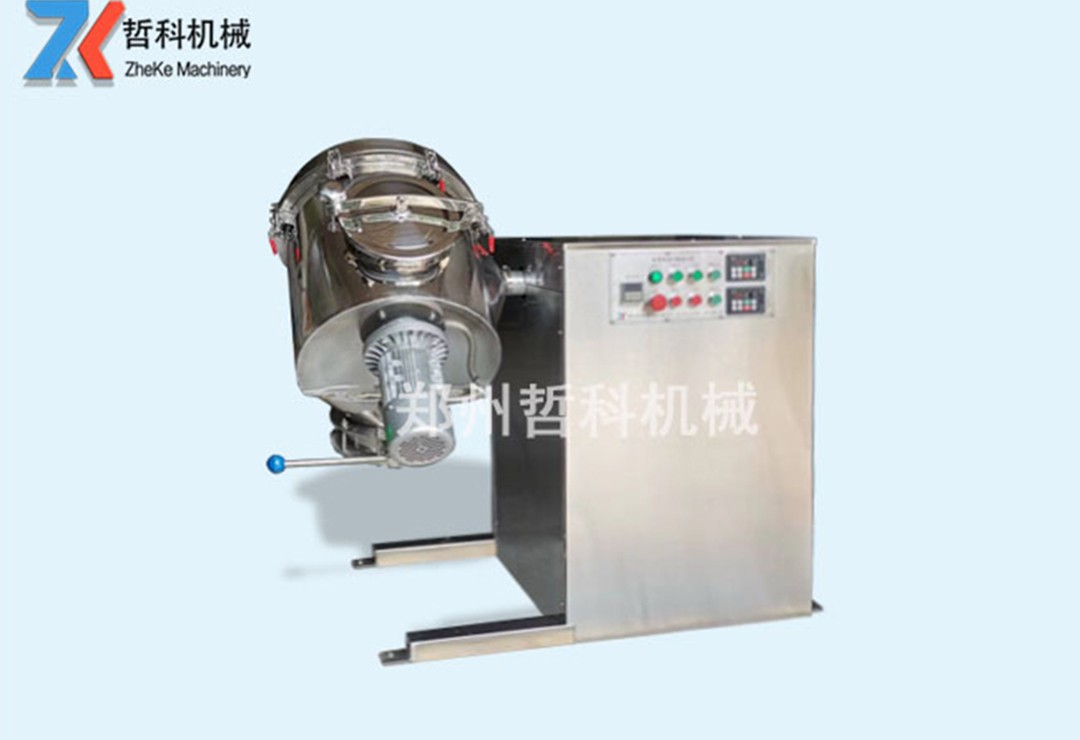

? ? Three-dimensional mixer features, three-dimensional mixer structure is simple, and no running components, maintenance maintenance is small, low energy consumption, is a new, high-precision granular material mixer equipment, commonly available for metallurgy, fertilizer, dye, pharmaceutical, food, fine feed, crude oil, metallurgical industry mining and other industries of a wide variety of powder equipment granular material mixing.

? ?The rapid development of three-dimensional mixer also gives convenience to the pharmaceutical industry, not only can mix a variety of lumpy Chinese herbal materials, while also further improving the mixing efficiency and mixing particle size. At this stage of the market, a variety of drugs and even a variety of food trends can not be separated from the dedication of three-dimensional mixer, so it can be said that three-dimensional mixer for the growth of the Chinese medicine and pharmaceutical industry has brought a very great convenience.

? ? Three-dimensional mixers are constantly used in people's daily life and are constantly developing trend in every industry. Because the mixer has a multi-directional movement, so that the barrel of the material mixing point, mixing effect is good, its mixing uniformity is higher than the general mixer uniformity. At the same time, the three-dimensional movement mixer volume than the general mixer volume more than double up to 85%.

? ?Three-dimensional movement mixer operation due to the mixing barrel body with a full range of multi-directional running action, so that a variety of materials in the mixing process, to accelerate the flow and diffusion, the barrel of the material cross-mixing points and avoid the general mixer due to the role of centrifugal force generated by the material specific gravity bias and accumulation of the phenomenon of mixing without dead ends, can effectively ensure the best quality of the mixture.

? ? Three-dimensional motion mixer barrel design program is different, the inner wall of the barrel after precision polishing, no contaminants, no dead ends, the material is discharged smoothly under the action of self-weight, does not leave the remaining material, with easy to discharge, no accumulation of material, easy to clean, etc., the material is mixed in a closed state, the working environment will not produce pollution.