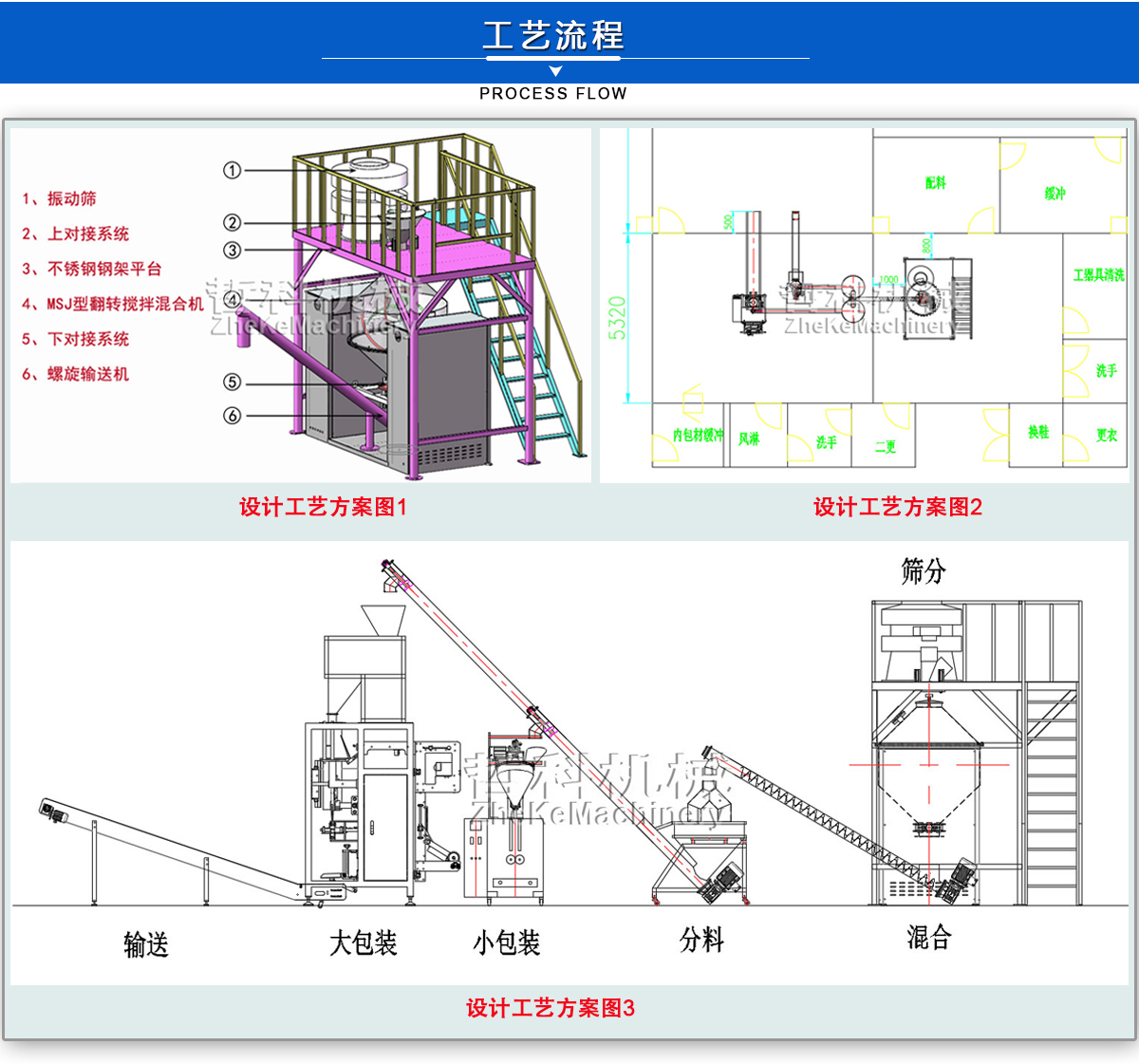

1. Feeding preparation: the mixer automatically aligns and the upper docking system is well connected to form a closed channel to prevent dust from flying;

2.Feeding: manually put the material into the vibrating screen, after screening to remove impurities, material automatically into the mixing machine barrel;

3.Automatic mixing: after feeding, the mixer will mix automatically according to the set time. When the time is up, the mixer will stop automatically and the outlet will find directly below automatically.

4.Discharge: the next docking system docking, the formation of a closed channel, the material automatically into the screw conveyor below, transported to the rear packaging machine for packaging.

The whole production line needs manual feeding, and all other processes run automatically with automatic control and monitoring by computer to prevent loss caused by human factors; The whole process is dust-free, and all interfaces are connected with dust bags to prevent dust from flying and improve the working environment of workers.

1. Simple operation, high degree of automation, just press the start button to complete automatic operation.

2. With the automatic control function of the equipment, you can switch between manual/automatic batching functions.

3. The production process is fully automatic to avoid the influence of human factors, improve product quality and reduce personnel costs.

4. Authority management, distinguish between managers and operators, realize the confidentiality of business information.

5. Compact structure, easy to install, easy to maintain.

6. Improve the working environment and prevent dust from flying.