Introduction of production line: This project is mainly used for automatic mixing production of food powder, including hopper, vacuum feeder, butt sealing cover plate, mixer, hopper. Using vacuum feeder feeding, reduce manual participation, prevent feeding dust flying.

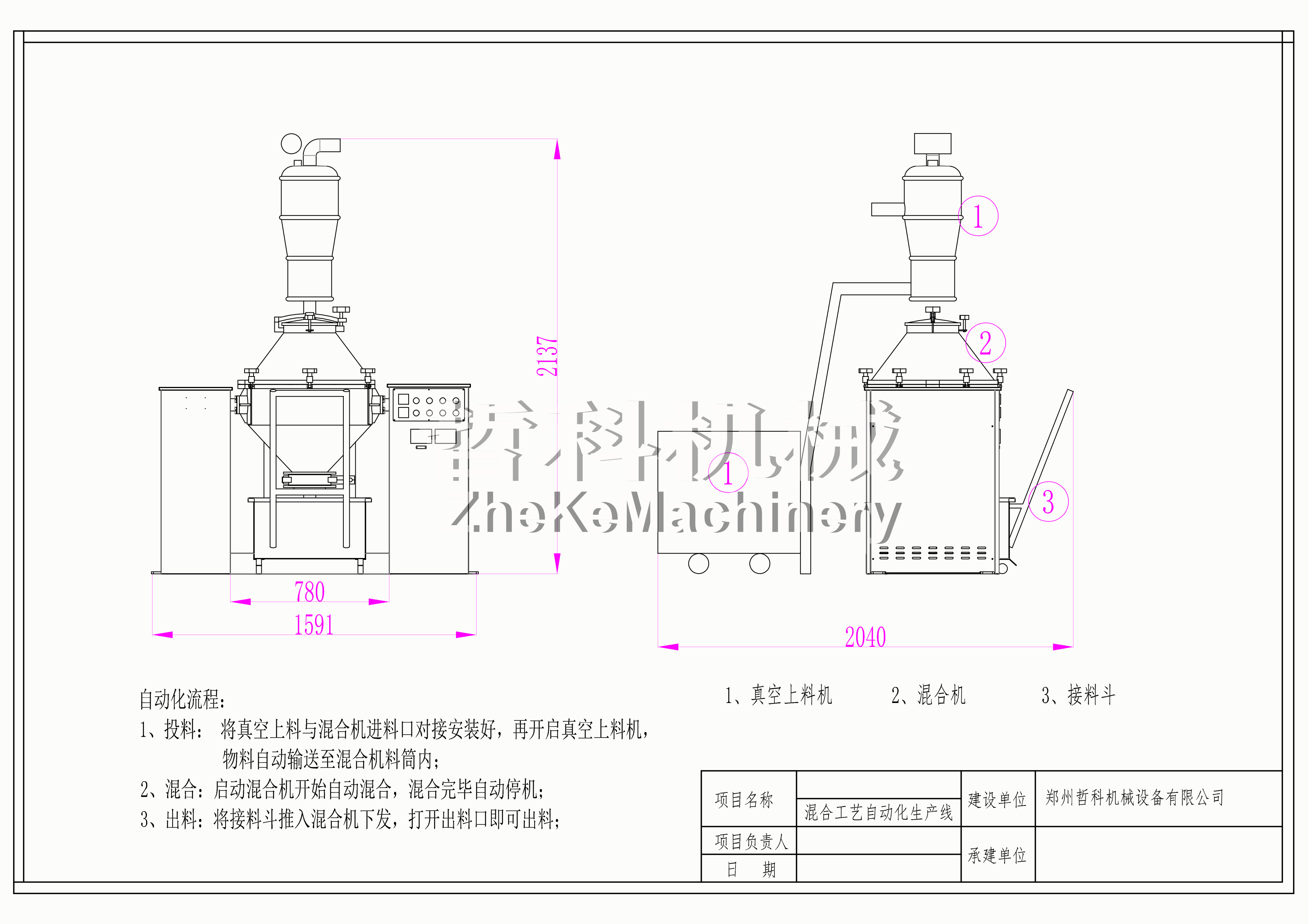

Production process:

1. Turn the inlet of the mixer to the top, and then connect the discharge port of the vacuum feeder and the feed port of the mixer through the butt sealing cover to keep the airtight channel to prevent dust from flying during feeding;

2. Start the vacuum feeder, put the materials to be mixed into the hopper, and the materials will be automatically transported to the mixer barrel. After conveying, close the vacuum feeder, remove the butt sealing cover plate, and close the feed port of the mixer;

3, open the mixer, the barrel continuous rotation, macro overall no dead Angle mixing, at the same time the barrel inside the forced mixing blade start positive, reverse automatic cycle rotation, fine forced shear, mixing, convection mixing, to ensure mixing uniformity;

4. After mixing, the mixer will automatically stop, transfer the discharging port of the mixer to the bottom, place the receiving hopper, and then open the discharging port. The material will automatically flow into the receiving hopper, and the mixing blade can be opened to prevent the material in the bucket from arching, and all the material will flow out without residue.

1. Simple operation, high degree of automation, just press the start button to complete automatic operation.

2. With the automatic control function of the equipment, you can switch between manual/automatic batching functions.

3. The production process is fully automatic to avoid the influence of human factors, improve product quality and reduce personnel costs.

4. Authority management, distinguish between managers and operators, realize the confidentiality of business information.

5. Compact structure, easy to install, easy to maintain.

6. Improve the working environment and prevent dust from flying.