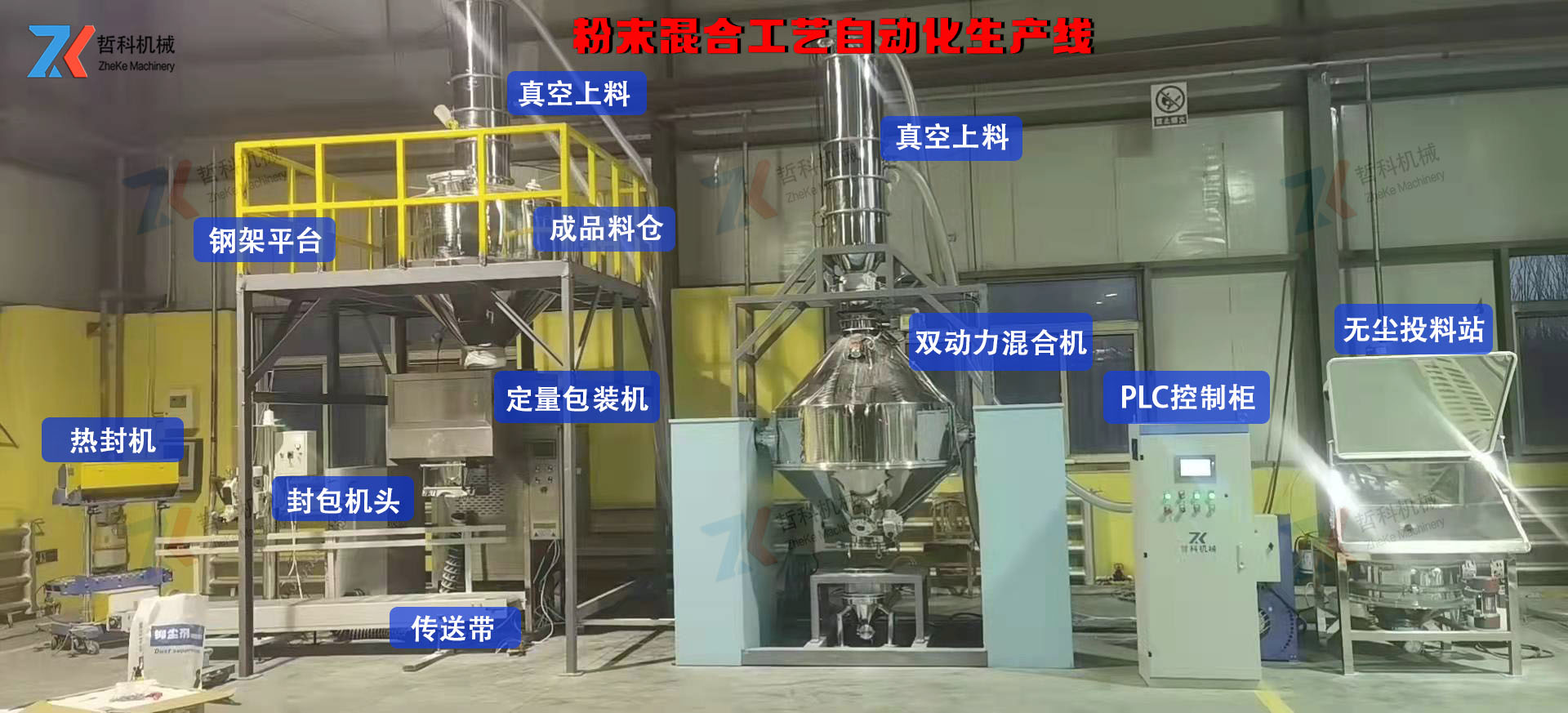

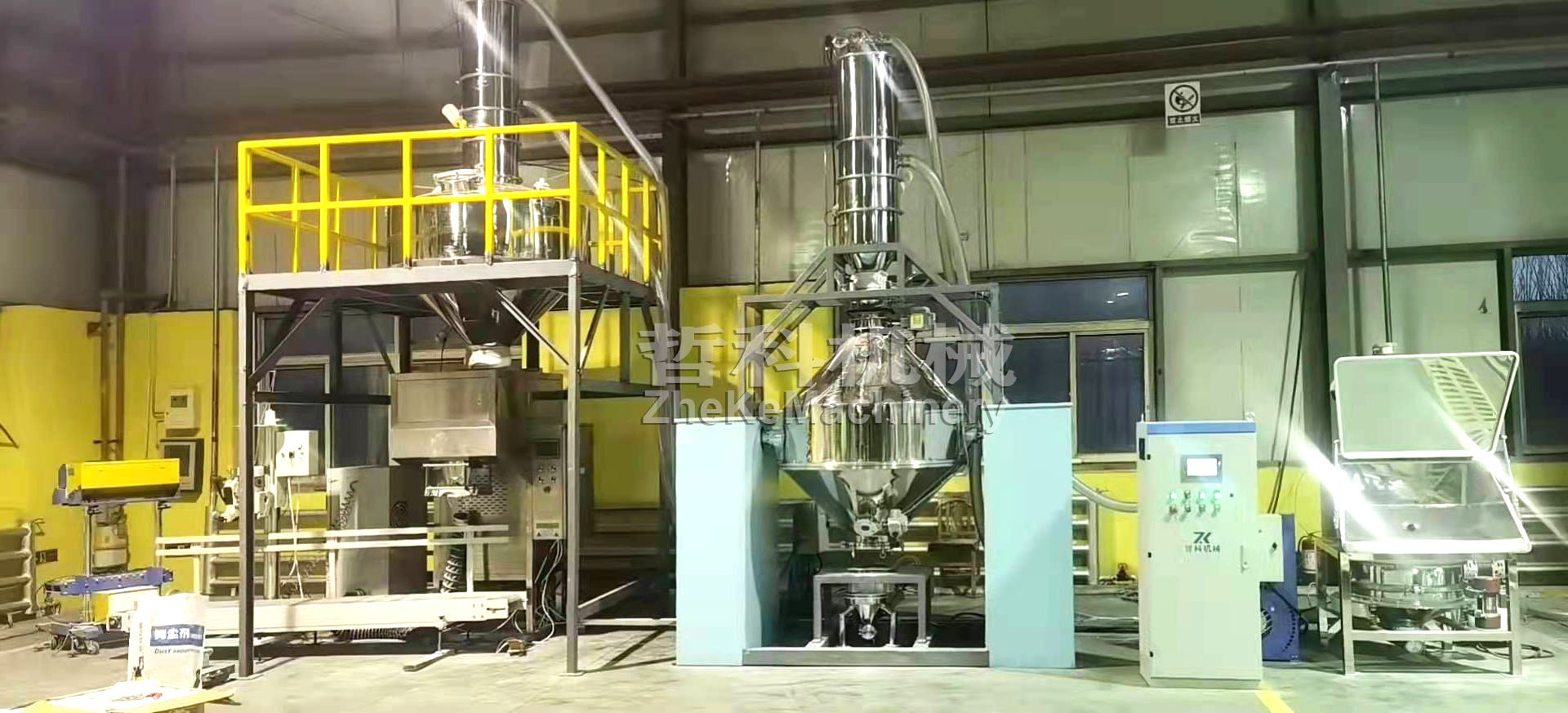

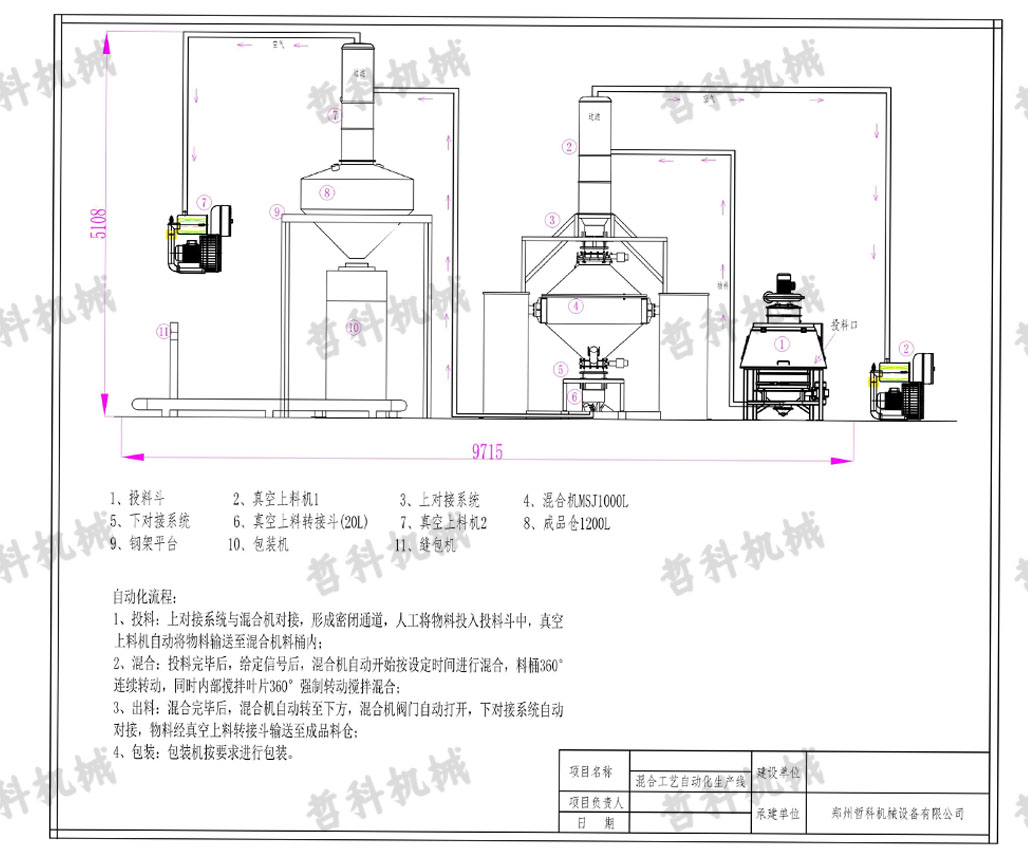

The entire production line, feeding manual feeding, the rest of the process is fully automated, mixer feeding, discharging the form of automatic docking, and to maintain a sealed, dust-free, to eliminate dust flying, to provide a good production environment.

1, Feeding preparation: before feeding, the mixer inlet is automatically aligned, the upper docking system is automatically docked to achieve a good seal, the valve automatically opens, waiting for the feed.

2, feeding: start the dust-free feeding station, manually pour the material into the feeding port, the material automatically into the mixer interior.

3, mixing: after the feeding is complete, the upper docking system vibrator work, the adherent powder vibrate to the mixer barrel, the valve automatically closed, the upper docking system automatically retracted, the mixer automatically began to work according to the set time to start mixing.

4, discharge: mixing time to, mixer outlet automatically under the alignment, the lower docking system automatically docked to achieve a good seal, receiving materials or subsequent process ready, the valve automatically opens, the material is transported to the finished product bin.

5, packaging: start the packaging machine, according to demand packaging can be.

The whole production line is controlled by PLC automation, including automatic and manual operation, the whole production process can be realized without dust and can be operated unmanned. The production line can be customized according to customer requirements, to meet the individual needs of customers.

1. Simple operation and high degree of automation, just press the start button to complete the automatic operation.

2. With fully automatic control function of the equipment, it can switch between manual/automatic dosage function.

3. The production process is fully automatic, avoiding the influence of human factors, improving product quality and reducing personnel costs.

4. Authority management, distinguish management personnel and operators, realize the confidentiality of business information.

5. Compact structure, easy to install, easy to maintain.

6. Improving labor environment and eliminating dust flying.